Amarinth, a world-leading, net-zero designer and manufacturer of low lifecycle cost centrifugal pumps and associated equipment, primarily for the offshore and onshore oil & gas industries; nuclear and renewable energy generation; defence; desalination; process and industrial markets, has completed a substantial £450K order from Harland & Wolff to replace obsolete Girdlestone pumps during the refurbishment of a former Royal Navy vessel that is now destined for service with the Lithuanian Navy.

Harland & Wolff, the British shipbuilding and fabrication company, secured a contract from UK Defence Equipment Sales Authority (DESA), awarded on behalf of the Lithuanian Government, to refit HMS Quorn, the former Royal Navy Hunt-class mine-hunting vessel. This decommissioned vessel was acquired by the Lithuanian Ministry of National Defence from the UK Ministry of Defence in 2020.

The vessel was equipped with seven Girdlestone marine pumps that after 27 years in service had reached the end of their operational life. Due to the discontinuation of Girdlestone’s business and the obsolescence of their pumps, Harland & Wolff were advised to work with Amarinth for a reliable solution, leveraging Amarinth’s two-decade expertise in supplying marine pumps and services globally.

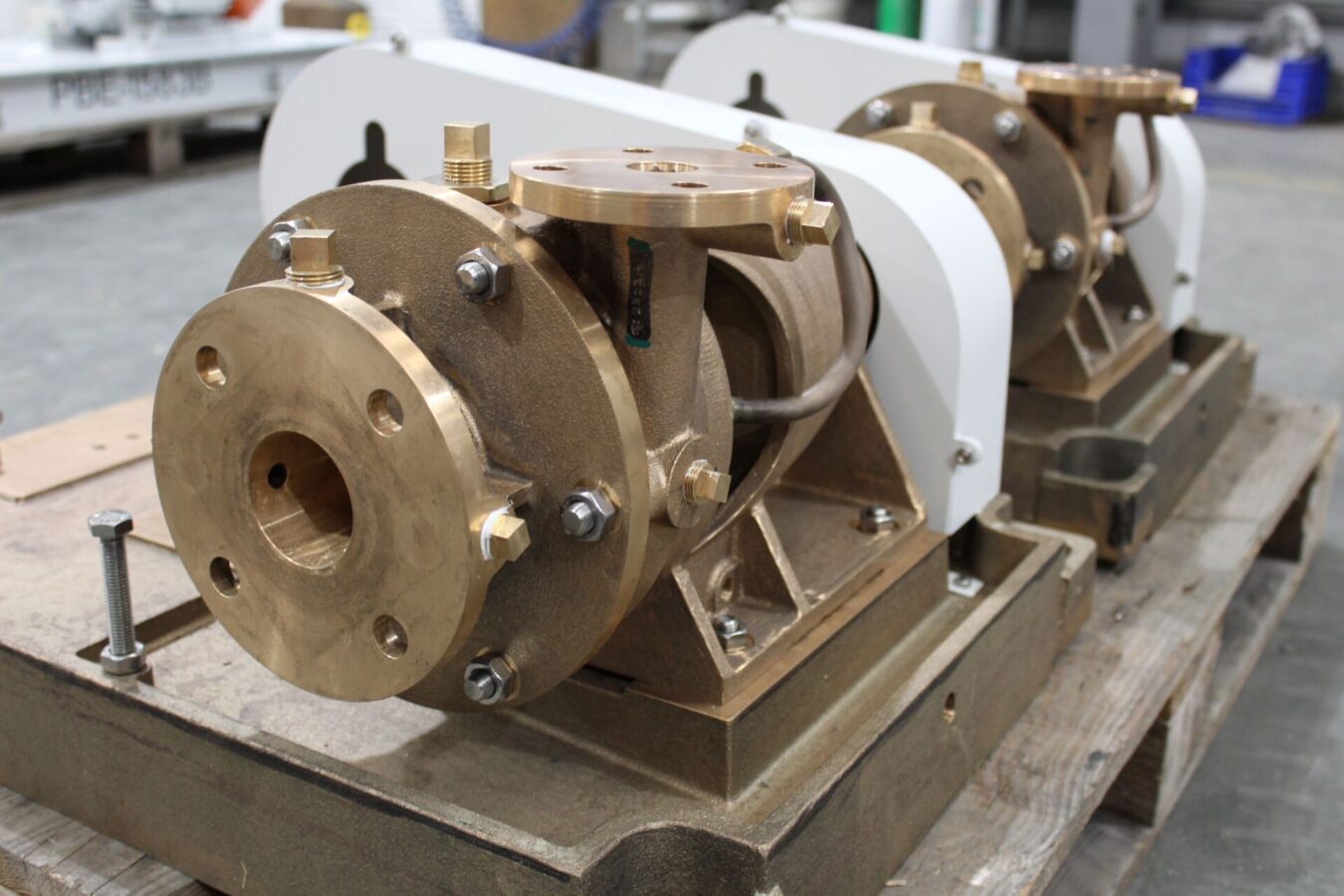

Obsolete pumps on vessels present significant challenges, often necessitating expensive modifications to accommodate the replacement pumps. In response, Amarinth engineered a range of marine pumps that seamlessly replace Girdlestone pumps with hydraulic and dimensional interchangeability. Furthermore, these pumps can offer enhanced performance and enable a straightforward transition without costly modifications to pipework and fittings.

A critical aspect of the project was the 32-week delivery schedule set by Harland & Wolff to align with the vessel’s refit window in Belfast, Northern Ireland. To control costs, Amarinth were also requested to conduct a strip and inspection of the old belt-driven Girdlestone pumps to see if any components could be reused. Following the assessment, it was decided the motors could be refurbished and so Amarinth collaborated with the original motor supplier on their overhaul to ensure the delivery schedule would be met.

Simultaneously, Amarinth commenced the manufacturing of the new pumps. For the harsh sea-water environment, marine pumps require robust materials and being for a naval vessel, the materials also had to be non-magnetic. Amarinth specified gun metal for the casings (a specific bronze alloy of copper, tin, and zinc) and strong nickel aluminium bronze for impellers and other components. Leveraging its close partnerships with UK foundries, which enables Amarinth to secure high-quality castings in exotic materials, the timely production, assembly, and testing of all seven pumps was achieved. The entire process concluded with the prompt delivery to Harland & Wolff in Belfast.

Expressing his satisfaction, Oliver Brigginshaw, Managing Director of Amarinth, stated, “We are delighted to have successfully delivered this initial order from Harland & Wolff, building on our success in servicing and supplying interchangeable pumps for obsolete Girdlestone models used on naval vessels worldwide. We look forwards to collaborating on future orders as more vessels undergo refits, providing reliable and fully supported pumps for decades to come.”